We routinely get questions about how often hardness testers need to be verified with test blocks by users. ASTM provides guidance in E 18 (Rockwell) and E 92 (Vickers and Knoop), Table A1.1, but the two standards use different terminology and have different requirements:

The Rockwell standard calls it « Daily Verification » and says it is:

- Required each day that hardness tests are to be made

- Recommended whenever the indenter, anvil, or test force is changed

The Vickers and Knoop standard calls it « Periodic Verification » and says it is:

- Required within a week prior to the machine being used

- Recommended each day that the machine is used

- Required whenever the machine is moved

- Recommended whenever the indenter or test force is changed

That’s as clear as mud! We would suggest the following set of rules:

You should run a test block(s) whenever…

- You are going to start testing for the day

- Shift/Operator change

- You change the hardness scale, anvil, or indenter

- You get out of spec readings on your parts

Doing it by these rules keeps you in compliance with the ASTM requirements, and also helps ensure that errors caused by a single operator, or by an instrument malfunction, are caught at the earliest possible time.

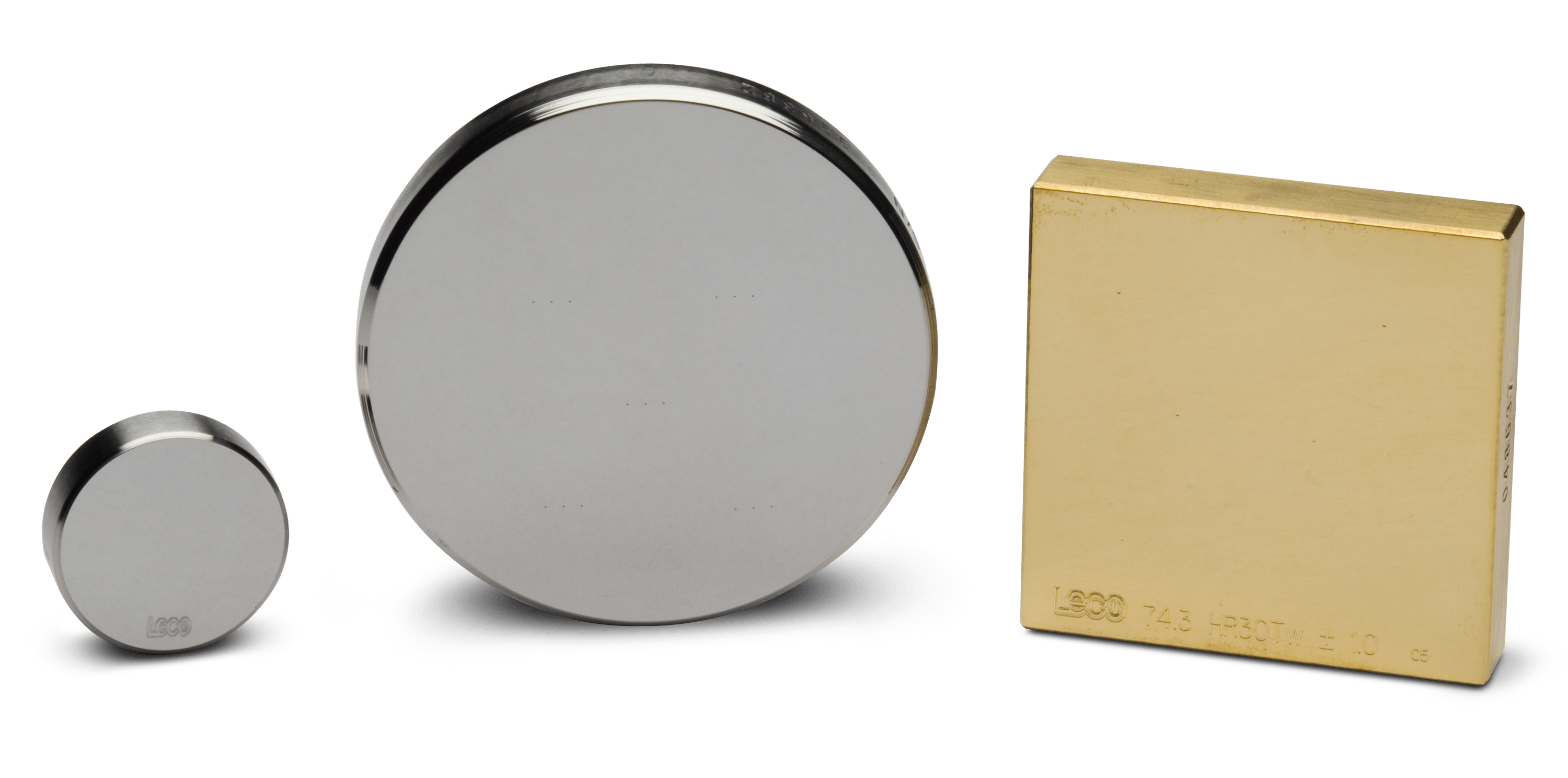

Used routinely and properly cared for, your test blocks will always keep you going in the right direction, and will serve as an unbiased referee when parts test out of spec.